Up close with Aircraft Services Account Manager Nadine Trutmann

“One of my last projects was with Edelweiss, a European-based leisure airline that contracted us to work on six Airbus A320s and to start on a sequence of Airbus A340 cabin modifications. Projects of this scale take a long time to plan in order to get things right and ensure that the aircraft’s ground-time is as short as possible. We put in a huge amount of work for getting everything ready for those few crucial days when the aircraft is with us.

During this project, we put a number of working hours to overhaul, modify and repair the aircraft. At our peak, we had up to 75 people working on a large aircraft on multiple shifts – including weekends – to make sure that the plane was back in the air as scheduled.

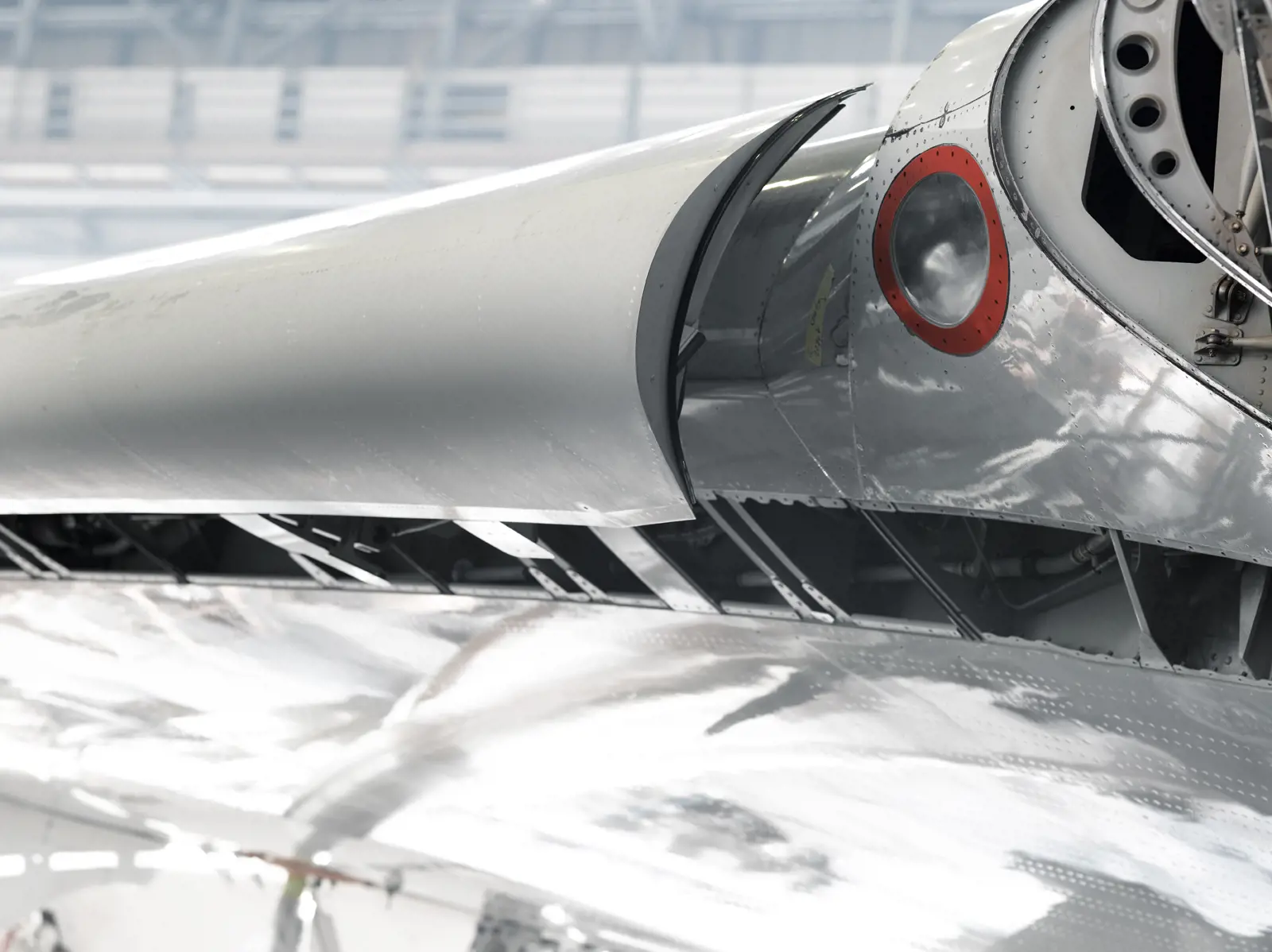

An Airbus A340 weighs in at nearly 300 tons at take-off and can carry over 300 passengers. It is a four engine long-haul aircraft that can fly non-stop for around 13,000 kilometers taking passengers half-way around the world. There are several variants of the A340 as the manufacturer upped the size and engine power over time.

Each aircraft has a specific work package that is determined by its life history and what maintenance and remodeling work it requires. Some only need minor work like paint touch-ups or the repair of damaged cabin parts; for others, landing gear overhauls or complete engine changes might also be involved.

A lot of what we do can be planned in advance. However, sometimes unexpected repairs pop up during an event, and then the whole team has to react immediately. Every day of delay has its cost. To prepare for these projects, I started almost a year before the first plane was scheduled to arrive. My role is to work as a contact point for to customer, so I receive the first request for a project. Since I handle contract manager tasks as well, I am also involved in background activities such as preparing quotes, finding slots, etc. When that work is finished, I go back to being the account manager and work closely with the customer.

At the design office, the job also starts over a year in advance to lay out the new designs and match them with the customer’s branding. Furthermore, elements like seats, galleys, lavatories or IFEs (Inflight Entertainment Systems) must match the customer’s expectations. Some items have a lead time of over a year and it is critical to have them on site when the aircraft arrives – every minute counts once the ground time clock is ticking!

When we remodel a new aircraft type at SR Technics, we also complete an official supplemental type certificate (STC) with the aviation authorities. Only few companies are able to draft and certify STC directly. As an account manager, it is exciting working on these projects from end to end: I get to see the job from all angles. Plus, by getting a grasp on what the customer needs and aligning these needs with the work we do, I am the first to hear how satisfied the customer is once the job is complete.

At the end of a project, we often share the success story with our employees and if client agrees also with the press. The feedback on the A320 modification was amazing. We got invited to the “Aircraft Cabin Maintenance Conference” (ACMC) in London to present the project to other operators and business leaders.

I love my job, because there is no better feeling than walking around these enormous planes and marveling at the technical expertise that has gone into making them, not to mention the knowhow that keeps them airworthy. Although we work behind the scenes, the quality of our work makes a big difference to the industry, and I am proud whenever I look into the sky and see one of my ‘projects’ soaring into the clouds. “

back to overview...